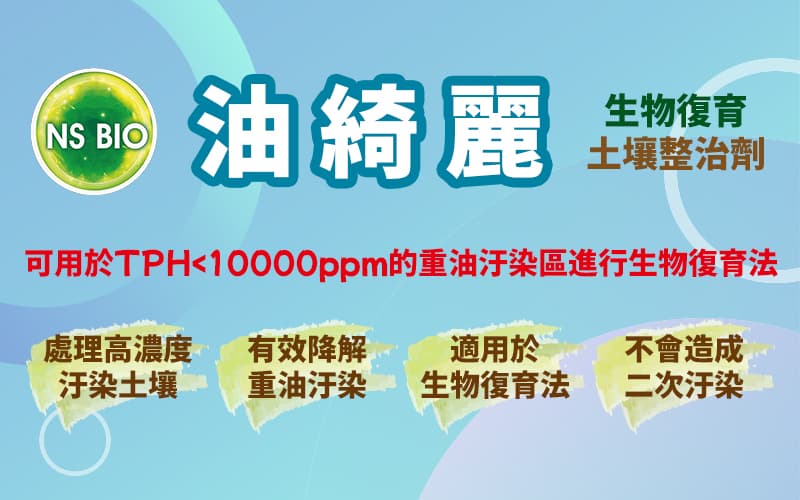

Oil Clean - Professional Heavy Oil Contamination Remediation Expert

🛢️ High Efficiency Oil Removal

Professional treatment for high concentration oil pollution below TPH 10000

🌿 Bioremediation

Actinomycetes technology natural decomposition, no secondary pollution

⚡ Rapid Response

Quickly establishes treatment microbial communities, accelerates oil decomposition

🏭 Wide Applications

Suitable for gas stations, petrochemical plants, industrial areas

🎯 Product Core Value

Oil Clean is a professional bioremediation soil treatment agent developed by New Sun Oversea, using unique actinomycetes technology, capable of efficiently handling various heavy oil contamination below TPH 10000, achieving environmental remediation solutions without secondary pollution.

Oil Clean is a professional bioremediation soil treatment agent, specifically designed for various heavy oil contaminated environments, especially high concentration contaminated sites below TPH 10000. The product uses advanced biotechnology, does not generate exhaust gas, wastewater or other secondary pollution, making it an environmentally sustainable oil pollution remediation solution.

Detailed Content Directory

1 Product Introduction & Application Areas

⛽ Gas Station Pollution

Professional petroleum product leakage remediation

- Gasoline diesel leakage

- Underground storage tank contamination

- Fuel dispenser area pollution

- Pipeline leakage treatment

🏭 Industrial Area Remediation

Comprehensive industrial oil pollution treatment

- Petrochemical plant pollution

- Machinery maintenance facilities

- Lubricating oil leakage

- Heavy oil contamination treatment

🚢 Special Sites

Special environment oil pollution remediation

- Port and dock pollution

- Ship oil spill treatment

- Airport oil pollution

- Traffic accident spills

What is Oil Clean?

Oil Clean is a professional bioremediation soil treatment agent developed by New Sun Oversea, with main components being actinomycetes and their metabolites. The product specifically targets high concentration oil polluted environments below TPH 10000, effectively treating various heavy oil contamination, including gasoline, diesel, lubricating oil and other difficult-to-decompose petroleum products.

Core Technology Principle

🔬 Advanced Bioremediation Technology

Oil Clean uses unique biotechnology, through ecological methods screening natural microbial combinations, generating the most suitable treatment microbial communities for current environment:

- Actinomycetes Technology: Special actinomycetes groups extracted from forest black soil

- Dynamic Adjustment: Automatically adjusts optimal treatment microbial communities according to environment

- Natural Decomposition: Converts pollutants into harmless substances

- Ecological Balance: Restores soil ecological function and balance

Professional Application Areas

Surface Oil Pollution Treatment

Professional cleaning of surface oil pollution in industrial areas, gas station spills, traffic accidents

Soil Oil Pollution Restoration

Ecological restoration of contaminated soil, restoring soil balance and function

Groundwater Pollution Control

Groundwater oil pollution control and purification treatment

Emergency Pollution Treatment

Emergency pollution incident treatment for ship oil spills, industrial accidents

2 Technical Advantages & Treatment Methods

🌟 Technology Advantages Beyond Traditional Methods

Oil Clean has obvious environmental and efficiency advantages compared to traditional physical-chemical methods

🚀 High Efficiency Treatment

Rapid decomposition technology

- Quickly establishes treatment microbial communities

- Efficiently decomposes heavy oil contamination

- Accelerates soil remediation speed

- Shortens remediation time

🌱 Environmental Safety

No secondary pollution solution

- No exhaust gas or wastewater generation

- Natural biological decomposition

- Eco-friendly technology

- Sustainable environmental solution

🔧 Convenient Usage

Simple and efficient operation

- Ready-to-use design

- No cultivation preparation needed

- Simple spray application

- Easy maintenance management

Professional Treatment Process

📋 Four-Stage Professional Treatment

- Pre-dilution: Oil Clean pre-mixed with water, ensuring uniform dispersion

- Enhanced Treatment: Combined with special powder agent to improve treatment efficiency

- Spray Inoculation: Uniform spraying to establish treatment microbial communities

- Pile Management: Establish treatment piles, regular maintenance monitoring

Two-Stage Treatment Technology

| Treatment Stage | Treatment Target | Technical Features | Applicable Oil Products |

|---|---|---|---|

| First Stage | Small molecule oil pollution treatment | Rapid decomposition of easily degradable oil products | Gasoline, diesel, etc. |

| Second Stage | Heavy oil contamination treatment | Specialized for difficult-to-decompose large molecules | Heavy oil, lubricating oil, etc. |

Professional Dosage Guide

| Treatment Stage | Oil Clean Dosage | Enhancement Powder | Dilution Ratio | Application Method |

|---|---|---|---|---|

| First Stage | 1~3‰ of pile weight | 2~4‰ of pile weight | 50-200 times | Uniform spraying |

| Second Stage | 1~3‰ of pile weight | Add as needed | 50-200 times | Multiple applications |

Accelerated Remediation Techniques

⚡ Methods to Improve Treatment Efficiency

- Increase Dosage: Adjust product dosage according to contamination level

- Increase Frequency: Regular addition to maintain microbial community activity

- Optimize Environment: Ensure good soil aeration and drainage

- Professional Monitoring: Regular testing and adjustment of treatment strategy

3 Product Specifications & Professional Guidelines

📦 Product Specifications

Detailed technical parameters

- Product Name: Oil Clean

- Product Purpose: Ecological restoration soil treatment agent

- Product State: Liquid

- Main Components: Actinomycetes groups, metabolites, water

🌡️ Environmental Adaptation

Usage condition ranges

- Temperature Range: 0~75℃

- Salinity Range: 0~5‰

- Odor Characteristics: Odorless

- Contamination Range: Below TPH 10000

⚠️ Important Reminders

Usage precautions

- Soil moisture 40-60%

- Avoid biological toxic agents

- Wait after oxidizer treatment

- Professional guidance recommended

Professional Usage Guidelines

📋 Key Usage Points

- Soil Moisture Control: Maintain 40-60% moisture, maintain microbial communities every 3-5 days

- Contamination Level Assessment: Higher oil content requires longer time, follow professional recommendations

- Microbial Community Dynamic Adjustment: Can add again to update microbial communities when treatment efficiency slows

- Safe Usage: Avoid concurrent use with biological toxic agents, wait after oxidizer treatment

- Flexible Adjustment: Flexibly adjust dosage frequency according to site conditions

🔍 Professional Monitoring Recommendations

To ensure Oil Clean achieves optimal remediation effects, recommend establishing complete monitoring and maintenance system:

- Regularly test soil TPH value changes

- Monitor treatment microbial community activity status

- Adjust moisture and aeration conditions

- Record remediation progress and effects

- Timely adjust treatment strategy

4 Technical Data Downloads

📄 Complete Technical Data

Download complete Oil Clean product catalog and technical description, including detailed application guidelines and success cases

Oil Clean Product Catalog

Complete technical specifications, application cases, effect evidence

Download PDF CatalogOil Clean Instruction Manual

Detailed usage guidelines, technical principles, precautions

Download Manual🤝 Professional Technical Support

Our environmental engineering expert team is always ready to serve you, providing customized oil pollution remediation solutions and technical guidance

🎯 Suitable Site Consultation

Whether it's gas station pollution, industrial area remediation or special site treatment, we can provide professional technical solutions

- Gas Stations: Petroleum product leakage, storage tank contamination, pipeline issues

- Industrial Areas: Petrochemical plants, machinery facilities, lubricating oil pollution

- Special Sites: Ports, airports, traffic accident sites

- Emergency Treatment: Ship oil spills, industrial accident emergencies